The bottom bracket

Crucial to the crankset is the bottom bracket. Of all the bearings on a bike, the bottom bracket is the one that has to bear the heaviest load. Not only does the bottom bracket have to spin while you pedal, but it takes the force of all the twisting and turning that occurs during pedaling.

There are two main types of bottom brackets:

✓ Adjustable: If you have an older or lower-end bike, you may have an adjustable bottom bracket. This type of bottom bracket has a cup that holds bearings and an axle that spins within the bottom bracket. An adjustable bottom bracket is much more susceptible to wear and tear than a cartridge-type (see the next bullet), because water and dirt can enter the cup where the bearings are held. Plus, an adjustable bottom bracket needs to be adjusted perfectly, or the bearings will prematurely wear out.

If you have this style of bottom bracket you may want to think of upgrading to a cartridge bottom bracket. At the very least, you’ll want to overhaul the bottom bracket at least once a year — more often if you do a lot of biking in wet or muddy conditions.

|

|

✓ Cartridge: Most newer bikes have a sealed-cartridge style of bottom bracket. A cartridge has a longer life than an ordinary bottom bracket — because they’re sealed, water and dirt are kept away from the bearings. They’re also easier to install and maintain because they don’t need to be adjusted the way standard bottom brackets with cups and cones do.

The other advantage to cartridges is that installing them is easier and quicker. When they do finally wear out, you replace the entire cartridge. But don’t worry — you’ll ride several thousand miles before you need to go shopping for a new bottom-bracket cartridge.

If the bottom bracket is squeaking or if the cranks don’t rotate smoothly by hand with the chain off, it’s time to overhaul. If you hear any squeaking or grinding, if the bottom bracket is slightly loose, or if you feel a vibration when you pull on the cranks, you should also prepare for an overhaul.

Adjustable bottom brackets should be overhauled as part of your annual maintenance. Cartridge bottom brackets are replaced rather than overhauled — and replacement isn’t usually necessary until you’ve ridden a few thousand miles.

Removing and installing a cartridge bottom bracket To remove a cartridge bottom bracket, follow these steps:

1. Remove the cranks following the procedure described earlier for the type of crankset you have (one-piece, cottered, or cotterless).

|

|

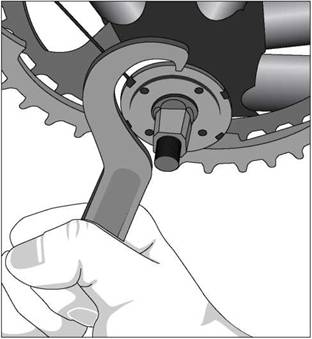

2. Attach the appropriate bottom bracket tool to the left side of the bike (as shown in Figure 13-11).

There are many different types of tools designed to fit many specific types of bottom brackets. The different tools usually have a different number of notches or splines, which match the number of notches or splines in the cup that secures the cartridge in place. Check with your local bike shop to determine which tool is appropriate for your bike.

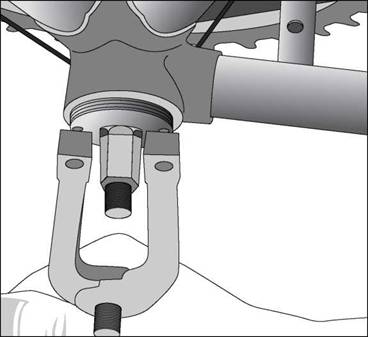

3. Use an adjustable wrench to turn the bottom bracket tool in a counterclockwise direction (as shown in Figure 13-12).

|

$ftNG/ |

|

|

The one common problem in removing cartridges is that the tools slip while under torque, stripping the splines. Because removing the bottom bracket can take a tremendous amount of force, the pressure needs to be applied on the tool in the direction of the bike to avoid stripping the splines or the tool.

|

|

|

|

|

Figure 13-11: Attaching a bottom bracket tool. |

|

|

|

Figure 13-12: Using the bottom bracket tool. |

4. Perform the same procedure on the right side except turn the tool clockwise.

5. When the lock ring is loose, use your hand to unscrew it the rest of the way.

It’s attached to the bottom bracket, which will come out when you’re finished unscrewing it (as shown in Figure 13-13).

To reinstall a cartridge bottom bracket, read the manufacturer’s instructions and follow these steps:

1. Coat the threads of the bottom bracket with grease.

Some bike shops prefer to use an anti-seize agent or plumber’s thread tape, which hardens and expands once it dries, helping to keep the bottom bracket secure and protecting the threads.

2. Examine the cartridge for an R and an L, signifying the right and left side.

3. Insert the L side into the right side through to the left side of the bottom bracket shell of the frame and carefully align the threads of the cartridge with the threads of the frame. Screw in the cartridge in a counterclockwise direction.

|

|

4. When it becomes more difficult to turn the cartridge, attach the bottom bracket tool.

5. Using an adjustable wrench, fully tighten the cartridge.

Most manufacturers recommend a significant amount of torque for the bottom bracket, which means you need to apply a lot of force to tighten the bottom bracket.

6. Attach the cup to the other side and, using a wrench, tighten it in a clockwise direction.

Removing and installing an adjustable bottom bracket

To remove an adjustable bottom bracket, follow these steps:

1. Remove the cranks following the procedure described earlier for the type of crankset you have (one-piece, cottered, or cotterless).

2. On the left side of the bike, you’ll see a lock ring with grooves cut into it. Unloosen the lock ring in a counterclockwise direction by using a specialized tool called a C-wrench (shown in Figure 13-14) or lock-ring wrench.

If you don’t have a C-wrench, use a chisel or — as a last resort — a flathead screwdriver to tap against the grooves or the lock ring to break it free. Be careful, because this may damage your screwdriver!

|

|

|

Figure 13-14: Using a C-wrench. |

3. After removing the lock ring, you’ll see an adjustable cup that holds the bearings. Remove this cap.

Some adjustable cups have pin holes which require a special tool. Figure

13- 15 is an example of using a pin spanner to remove the adjustable cup. Unscrew the adjustable cup being careful to catch any loose bearings that may exist. The axle will slide out at this point.

|

|

4. On the right side of the bike, remove the fixed cup, which is screwed into the bottom bracket shell of the frame.

You may not be able to remove the fixed cup, so consider taking the bike to your local bike shop where they’ll have a fixed-cup removal tool.

You’ll need a large enough crescent or adjustable wrench to fit around the fixed cup. This time, turn in a clockwise direction. This side may be very tight.

To install an adjustable bottom bracket, follow these steps:

1. Clean all the parts with degreaser.

2. Inspect the ball bearings, cups, and axle.

|

|

|

Figure 13-15: Using a pin spanner. |

If they look dull or the bearing surfaces are not smooth, replace them.

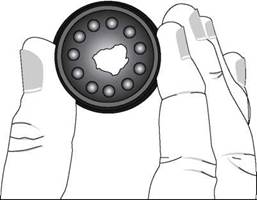

3. Fill both cups with a layer of grease.

4. Place the same number of ball bearings in that were originally each cup.

If you aren’t sure of the number, use as many as necessary to fit securely with a small gap to allow each bearing “elbow room.”

5. Use a screwdriver or other tool to push the bearings into the grease.

6. Cover the bearings with another layer of grease.

|

|

|

Figure 13-16 has an example of bearings packed in grease. |

|

in grease. |

|

Figure 13-16: Repacking the bearings |

7. On the right side, screw on the fixed cup by hand until it tightens. Then very firmly tighten this side with a wrench.

8. On the left side of the bike, insert the longer end of the axle into the bottom bracket shell and into the fixed cup.

9. Screw on the adjustable cup until tight. Try rotating the axle. If it’s tight, slightly loosen the cup.

10. Place the lock ring on the bottom bracket and tighten, checking to ensure that the axle rotates smoothly and not too tightly.

It may take a few tries to get an adjustment that is not too tight and not too loose.

Shopping for a new crankset and bottom bracket

If you have an older bike and you’d like to upgrade the crankset and bottom bracket, there are a few things to think about:

✓ Buy a cartridge bottom bracket. This is the most popular style of bottom bracket on the market and shouldn’t be a problem unless your bike requires a special bottom bracket. When the cartridge bottom bracket is in place, you’ll be able to relax knowing that most likely you won’t have to touch it for a number of years.

✓ If you’re moving from a cottered crankset to a cotterless one, you’ll to need replace both the cranks and the bottom bracket. You can’t mix a cottered crank with a cotterless bottom bracket.

✓ Make sure that the axle style and the threads match. There are different types of bottom bracket threading. The threads need to match your frame and the axle style needs to match the crankset.

Consult with your local bike shop to confirm which bottom brackets will fit the threads on your bike.

✓ Make sure you have the right size bottom bracket. There are many different widths for bottom brackets. You need to know the width of the bottom bracket shell on the frame and the overall length needed for the specific crankset you’re using. Sometimes mountain bikes have wider bottom brackets than road bikes. In addition, cranks with three chainrings need wider bottom brackets than two-chainring cranks.

Again, talk with the folks at your local bike shop to make sure you’re getting the right size for your bike.

✓ Pay attention to crank-arm length. Crank arms change the circumference in which the pedals rotate, so with larger crank arms you’ll be pedaling in a wider circumference and getting more leverage as you pedal. Having longer cranks and more power is beneficial if you’re doing a lot of climbing. The downside of a larger crank is that, because of the wider circumference, it takes more effort to spin quickly — so if speed is a consideration, a smaller crank may be in order.

The most common crank-arm lengths are 172.5mm or 175mm. If you’re a short person, you’ll want to try using a shorter crank. At the same time, if you’re tall, a longer crank will work with your leg muscles better. A few manufacturers sell cranks of 185mm or more. The best advice is to work with your local bike store to find the crank the best suits you.

With longer crank arms, it’s important to make sure the bottom bracket has enough clearance or else the crank arms could hit the ground when you’ re cornering or climbing over logs.