Don’t Screw This Up: The Threading System

If you’re like most people, you probably think you know the basics of how threads work, but we promise you’ll be surprised by how much science there is to the basic concept behind a nut and bolt.

Why is this important? Of all the activities you’ll perform while working on a bike, tightening and loosening threads on a bike is at the top of the list. Improperly handle something as seemingly innocuous as a nut or a bolt, and you could irreversibly damage the threads of an expensive component on your bike.

Threaded fasteners are the unsung heroes of the biking world. Although they’re essential to keeping your bike together as it rolls on down the road, they’re so inconspicuous that people rarely notice them. About the only time they come to your attention is when something on your bike starts making a rattling sound, usually due to a fastener being loose.

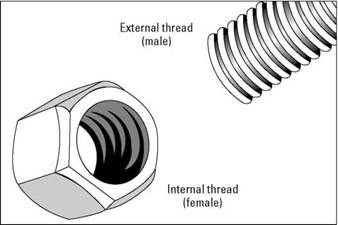

Fasteners are heterosexual partners. They consist of a male part (such as a bolt) and hollowed female part (such as a nut), as shown in Figure 2-4. Male and female parts, designed to work together, are cut with complementary matching grooves that allow them to be threaded together.

|

|

|

Figure 2-4: Male and female threads on a nut and bolt.

|

Different fasteners are designed to handle different amounts of force. The bolt used to hold the water-bottle cage in place would not provide enough force to secure a crank.

Tightening enough, but not too much

The one thing you need to know about fasteners — and never forget — is this:

Never over-tighten a fastener.

When Dennis learned this concept, it was like a revelation. He had always assumed that the rule was: The tighter, the better. If someone had shared this all-important rule with him earlier, he could’ve saved himself from ruining a number of fasteners.

Fasteners stretch and flex when tightened, which gives the joint force to stay in place. Over-tightening the fastener can cause it to stretch to such a degree that the joint becomes damaged.

You don’t have to freak out the next time you have to tighten a nut or bolt. The general principle is to tighten it a bit, and then check it: If there’s still some play in the part, tighten it a little more.

|

|

If we’ve made you paranoid about over-tightening, you can always purchase a torque wrench. Bike mechanics use these in order to apply exactly the right amount of force when tightening a fastener.

|

|

If you’ve made like the Incredible Hulk and ended up damaging a thread, the folks at your local bike shop may be able to recut it using a tool called a tap. Of course, this assumes that the damage to the thread was minor and that there’s still enough undamaged thread remaining. If not, the thread may be irreversibly damaged.

Clean and lubricate all threads before tightening them. For smaller fasteners, a liquid lubricant will do the job. For thicker fasteners (such as the thread of a bottom bracket), a heavier lubricant such as grease is recommended.