Reassembling the hubs

When you’re all done overhauling the hubs, it’s time to reassemble them. To reassemble the hubs, follow these steps:

1. If you removed the dust seals, press them back into place.

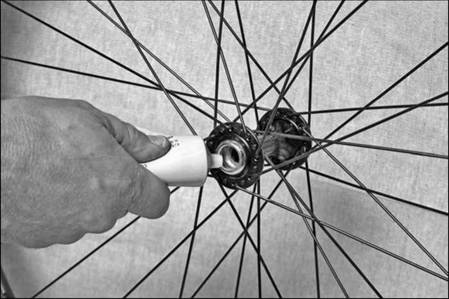

2. Apply a fresh layer of grease to each of the cups (as shown in Figure 7-8).

The general rule is to use enough grease so that a bearing will be covered halfway when placed in the cup.

3. Using tweezers or pliers, place half the bearings in one cup, spreading them out evenly across the cup (as shown in Figure 7-9).

The bearings should be held in place temporarily by the grease. Make sure there is at least a 1mm gap between all the bearings placed in the cup. If the bearings are too tight, remove one, so that each bearing has a few microns of elbow room.

4. Grease the axle and slide it halfway into the hub to hold the bearings in place while you fill the other cone with bearings.

Make sure that no bearings fall out during this procedure.

|

|

|

Figure 7-8: Filling cups with new grease. |

|

|

|

Figure 7-9: Inserting the bearings. |

5. While you’re holding the axle with one hand, place the other half of the bearings into the other cup.

After you’ve finished with all the bearings, slide the axle the rest of the way through.

6. Thread the cone onto the axle until it begins to press against the bearings in a secure fashion.

Twist the axle to ensure that the bearings are snug and in place.

7. Slide the washers and any spacers on in the axle in the correct order.

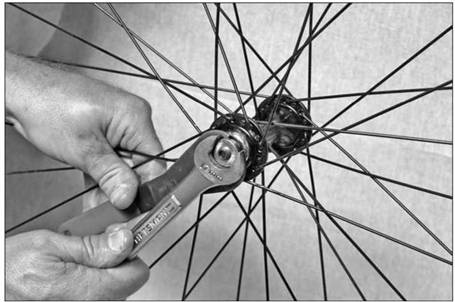

8. Thread the locknut onto the axle by hand (as shown in Figure 7-10) and, after it tightens, use a wrench to tighten it further while holding the cone in place with a cone wrench.

|

|

You don’t want to tighten the cone, because it could press forcefully against the bearings and damage them.

When tightening the locknut, leave a slight amount of play in the axle so that it can accept the additional force from the tightening of the quick — release lever.

9. Adjust the tightness of the hubs by following the procedure in the next section.

|

Figure 7-11 shows an example of tightening the cones in the hub.

|

Figure 7-10:

Attaching the locknut.

|

|

|

Figure 7-11: Tightening the cones. |

Adjusting a hub

The cones on a hub cannot be too loose or too tight — they need to be just right. What does that mean exactly? The tightness should be such that there is little to no play in the hub, but the axle rotates freely. If you have trouble finding the right point between too loose and too tight, err on the side of being slightly loose.

|

|

To adjust the tightness of a hub, you need a wrench for the axle locknuts and a cone wrench to fit the cone. To tighten the hub, hold the cone in place with the cone wrench and tighten the locknut with your other wrench. Only the locknut should move; if the cone is moving, it could press against the bearings and damage them. To loosen the hub, loosen the locknut.

If only a small adjustment is needed in the hub, you can adjust the locknut and cone on just one side of the bike.

Whenever you adjust the hubs of a wheel that uses quick releases, leave the cones just a little loose. Tightening the quick release will apply extra pressure to the bearings and take that little wiggle out when clamped in the frame. Be sure to check the adjustment once the wheel is clamped into the bike.