Hubba-Hubba: Working on the Hubs

Hubs have to hold up under significant pressure and, over time, water, dirt, and grime work their way into the bearings and can cause this pressure to wear them out. The best solution for keeping them in good working order is to perform an overhaul of the hubs at least once a year as part of your annual service — more often if you ride a lot or in wet or muddy conditions.

Hubs are designed to allow the wheel to effortlessly spin around an axle. Bearings inside the hub reduce friction as the axle rotates. If you hear a grinding sound or the wheel doesn’t rotate smoothly, it may mean that the hub is too tight and should be adjusted or that an overhaul is in order. If you can wiggle the axle back and forth, this may mean that the hub is too loose.

There are two main styles of hubs:

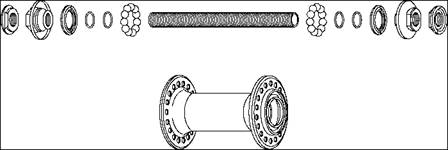

✓ Cup-and-cone (see Figure 7-4): In the cup-and-cone style, loose ball bearings sit in smooth cup and are held in place by a cone. The cone and cup together create a race, in which the bearings can move around the axle in a circle with minimal friction. Washers are used to properly space the cone and cup and a locknut holds everything in place on the axle.

|

|

|

|

|

Figure 7-4: A cup-and- cone hub. |

✓ Sealed bearing: The sealed-bearing hub is popular on many midrange to high-end bikes. This style of hub also has a an axle, bearings, race, and cone, but they’re assembled as a unit and sealed when they’re manufactured to improve their ability to keep water and dirt away from the bearings. Some sealed-bearing hubs can be serviced; others need to be replaced when they give out. The good thing is that they last much longer than cup-and-cone hubs.

Don’t be fooled by the label sealed mechanism. These are standard cup-and- cone-style bearings, except they have a rubber seal to help keep contaminates out. They aren’t true sealed bearings.

Overhauling the hubs

Well-functioning hubs are critical for smooth spinning wheels and a comfortable ride. To keep your hubs in the best possible shape, plan on overhauling the hubs at least once a year. If you’re lucky enough to have sealed-bearing hubs you’re off the hook; most of these will last many years without any service. If you have cup and cone hubs, follow these steps:

1. If you have a quick-release skewer, remove it from the wheel. If there are nuts on the hub remove them with a wrench, alternating side to side as you loosen.

2. Using a cone wrench and a second standard wrench, make sure the cone and locknut are tight against each other on one side of the hub.

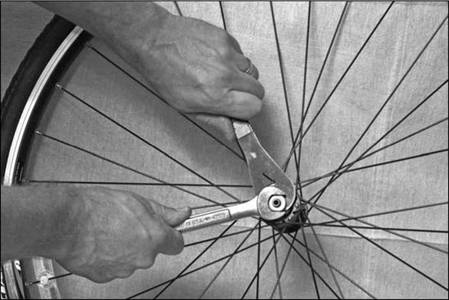

3. On the other side of the hub, using a cone wrench, secure the cone in place while you loosen the locknut in a counterclockwise direction on the same side of the hub (see Figure 7-5).

It will usually require some force to initiate movement in the locknut.

If you’re working on a hub with a freewheel, remove the freewheel (see Chapter 11 for instructions). If you have a cassette hub, work on the side opposite the cassette.

4. Remove the locknut, washers, and cone from the axle, keeping them in order as you remove them.

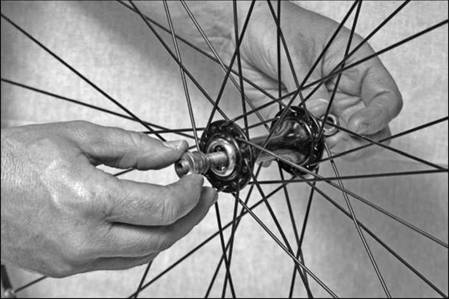

5. Hold a towel or cup under the hub as you pull out the axle, because some bearings may fall out.

Figure 7-6 illustrates the removal of an axle.

Leave the cone, washers, and locknut in place on the other side of the axle. This will make reassembly easier.

6. Using a screwdriver, remove the bearings from both sides of the hub (see Figure 7-7).

A magnetic screwdriver makes bearing retrieval easier, although a screwdriver tipped with grease will work. Another trick is to push them down through the center of the hub and out the other side.

|

|

|

Figure 7-5: Undoing the locknut. |

|

|

|

Figure 7-6: Removing the axle. |

|

|

|

Figure 7-7: Removing the bearings. |

Count the bearings in the hub. Some hubs are designed for ten bearings in the front and nine in the back. Because you’ll probably want to replace the bearings with new ones (they’re cheap), you’ll want to know how many to purchase (and how many to use for reassembly).

7. After the bearings are removed, wipe the inside of the hub shell with a cloth and then use a degreaser to clean the cups.

Examine the cups for wear. If they have dents in the surface, you may need to replace the entire hub.

8. Clean the axle, nuts, and cones by removing dirt and grime from the threads.

Examine them for signs of wear and tear. If you roll the axle across a flat surface and it wobbles, it may be bent and need replacing.

9. Wipe down the dust seals with a cloth.

If they’re especially dirty, you can pop them off using a screwdriver for leverage.

10. After cleaning all parts, allow them to dry thoroughly before reassembly.